A mini FabLab at IAS !

The design office / workshop is equipped with a new prototyping workshop !

In order to be able to quickly produce prototypes and improve our responsiveness during the development phases, the IAS is acquiring two new facilities: a 3D printer and a 5-axis digital milling machine. This equipment allows our laboratory to slowly enter the era of digital manufacturing while developing new skills.

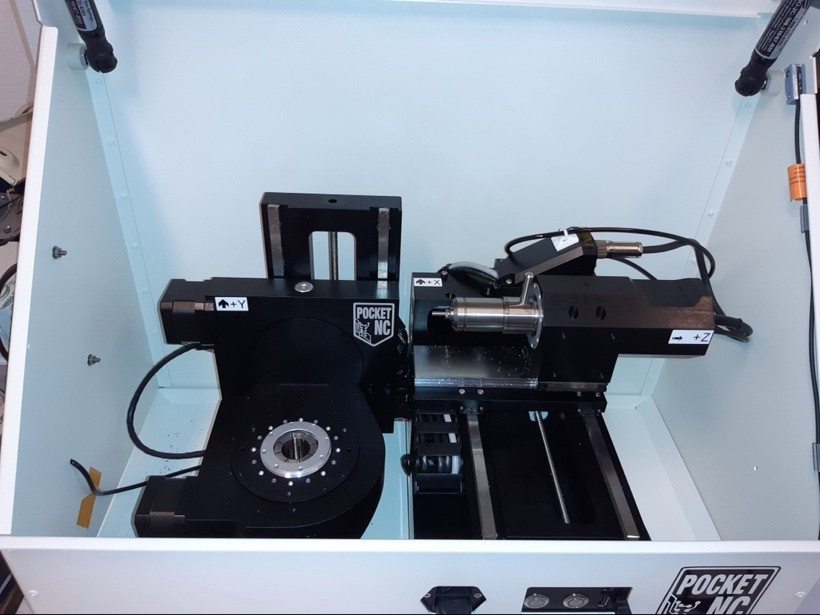

Thanks to the 3D printer (Picture 1), prototyping parts of the order of 30cm with an accuracy of 0.1mm can be produced in plastic by additive manufacturing. The actual size of the parts, the procedures for their integration can then be checked, and preliminary measurements in order to carry out the routing of the electrical harnesses is therefore facilitated. The CNC milling machine (Picture 2) allows for 5-axis machining of 10cm side parts for test models. This switch to digital controls within the IAS gives our design office and workshop the means to converge efficiently to the right design during the R&D phases and to train the youngest in these new technologies.

The mini FabLab represents an investment of more than 20kE financed thanks to the ARIEL and Solar Orbiter (PHI) projects.

Contact at IAS : Mehdi Bouzit

Picture 1 : SLA 3D printer

Picture 2 : 5 axes milling machine : continus POCKET NC